One of the key problems of modern aquaculture is the beneficial use of protein (NPU – net protein utilization). Beneficial use of protein is the ratio of the number of amino acids converted into protein to the number of consumed amino acids. At the moment, in the conditions of RAS (recirculating aquaculture system), this indicator reaches only 25%. That is, 75% of the protein in feed is not used properly. And protein, as you know, is the most expensive component of fish feed, and its low use leads to an increase in the cost of grown products.

In addition, unused protein is deposited in the form of waste, the processing of which requires a certain amount of energy. In addition, a huge amount of nutrients accumulate in the water, which are not used properly.

So we are faced with a situation where we spend a lot of money on the purchase of feed, then use a huge amount of energy to process the waste, and at the same time deprive ourselves of ways to intensify our aquaculture. In addition, we bear large capital costs for the organization of water filtration in RAS. But we will return to that at the end of this article.

What can we do in this situation? In principle, it is easiest to do nothing. Just continue to work the old fashioned way, growing fish in an extensive way. At the same time, it is desirable to reproach the state for not giving you something, not doing it, and that is why everything is bad for you.

The second option is the introduction of ASD technology. Unfortunately, in our limited financial conditions, the construction of RAS using the latest technologies is very expensive. Moreover, even the most modern technologies do not allow to achieve a higher level of beneficial use of protein. This can be done only by developing special feeds that allow to increase this indicator.

We are lucky that we live in a period of active development of aquaculture, which is associated with a decrease in the reserves of the World Ocean. This pushes scientists and farmers to minimize the use of expensive feeds, which leads to the development of new technologies to increase fish productivity.

BFT

One such technology is bioflocculation technology. Thanks to its implementation, we will be able to increase the beneficial use of protein up to 50%. Let’s try to understand this technology.

BFT is a method of improving water quality due to the balance of nitrogen and carbon in the system.

Biofloc – an accumulation of macro- and microphytes, including diatom algae, protozoa, bacteria, fungi, as well as the remains of dead animals, feces and other organic matter. As a result of the symbiotic clustering, we get colonies with a high level of microbial protein, which is consumed by fish and crustaceans.

This technology has recently been recognized as a sustainable (self-sufficient) method of water quality control with additional protein production in the environment.

Developed by Dr. Avnimilech in Israel in the late 1990s, where it is widely used for commercial tilapia cultivation. This technology is also used for the cultivation of marine shrimp of the genus Penaeus (vannamei, tiger shrimp). This is the most productive way of growing crustaceans today.

The microbial protein produced by this technology has a much higher nutritional value than the protein found in commercial feed. This leads to a reduction in feed costs by 25-30%.

Biofloc is an accumulation of macro- and microphytes, including diatom algae, protozoa, bacteria, fungi, as well as the remains of dead animals, feces and other organic matter. As a result of symbiotic accumulation, we get colonies with a high level of microbial protein, which is consumed by fish and crustaceans.

How to create favorable conditions under which highly nutritious flakes are formed?

The first thing we do is limit water exchange. This technology is also called technology with zero exchange (zero exchange system). That is, water is added only as it evaporates.

This leads to the accumulation of organic waste, which is used to feed heterotrophic bacteria (heterotrophs, organisms that use ready-made organic compounds for their nutrition).

At the same time, we forcibly mix the water with the help of air and water pumps, which leads to the creation of ideal conditions for the growth of bacteria. During the maturation of bacterial flakes (colonies), autotrophic nitrifying bacteria develop on them, which allow us to process inorganic substances (ammonia, nitrites) into organic matter, which are then consumed by heterotrophic bacteria.

Thanks to constant water quality control, we can adjust water parameters by adding the necessary amount of nitrogen or carbon. It is thanks to the correct ratio of these basic substances that we have the opportunity to achieve conditions under which all organic material is processed and bacterial flakes rich in microbial protein are formed.

Fish and crustaceans eat bacterial flakes, which leads to significant increases in fish productivity, because thanks to these processes, feed is re-assimilated.

This is a kind of biomimicry, that is, the repetition of natural mechanisms in controlled artificial conditions. In fact, nature has long had effective methods of solving the problem of processing organic waste. We only have to master them and intensify the production of fish products as much as possible.

Productivity of BFT

This technology is suitable for growing all types of fish that feed on phytozooplankton (detritophages too). BFT is one of the most popular technologies for growing crustaceans, in particular vannamei shrimp.

Tilapia is one of the most common objects of world aquaculture. This is an extremely important fish for the nutrition of many peoples of the world. Thanks to the active cultivation of this type of fish in aquaculture, many poor countries of the world partially solve their food problems.

Basic data on the productivity of bioflocculation technology:

- up to 40 kg of tilapia per 1 m3

- 2 kW per 1 kg of grown products

- waste-free production

- possibility of water reuse

- feed coefficient for tilapia below 0.9

- up to 8 kg of shrimp per 1 m3

- feed coefficient for shrimp in the region of 1.3 (tilapia – 0.9)

Investment

В compared to the RAS technology, the capital costs of which reach the level of 10-12 Euros per 1 kg of grown products per year, the BF technology is much cheaper to implement. The cost of capital expenditures for the implementation of this technology will cost a farmer somewhere in the region of 3-4 Euros per 1 kg of products grown per year. Which makes it possible to immediately reduce the cost of products grown in such conditions.

The construction of a small farm for growing 30,000 kg of tilapia per year can cost somewhere around 2.5 million hryvnias (not including the cost of land). Such a farm can earn in the region of 1 million. hryvnias per year, which makes this investment quite attractive in today’s economic conditions.

https://www.youtube.com/watch?v=G1-8TkkdQtI

Our shrimp farm

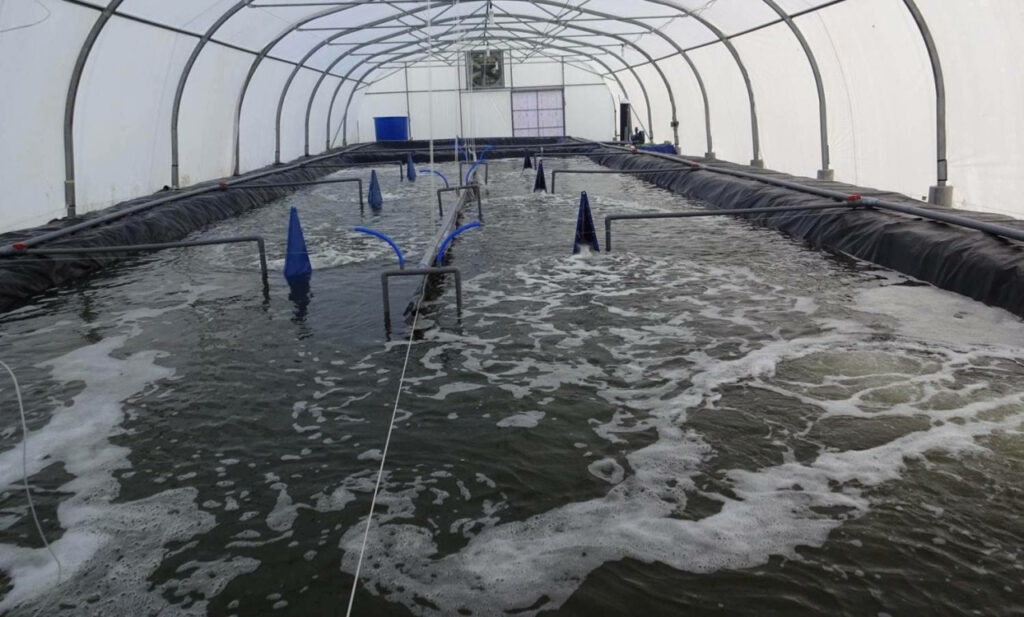

5 months ago near Kyiv, our company started construction of the first farm in Ukraine for growing Pacific white-legged shrimp Penaeus vannamei, which is also called vannamei for short. This species of shrimp is the leader in the cultivation of crustaceans in the world.

https://www.youtube.com/watch?v=9TL7gVBHhFw

Basic data on our farm:

● Calculated for 5000 kg of cultivation per year

● 4 pools of 90 m3

● 3 cycles of cultivation per year (120 days each)

● The possibility of obtaining the first harvest already after 60 days

cultivation (shrimp 10 grams)

● BF technology

● Greenhouse 450 sq.m.

● Fuel for 160 kW (solid fuel)

● 8 km from Kyiv

Our farm is an educational and research farm, where in the future specialists from other farms will be able to undergo training in crustacean cultivation technology. At this stage, we are already growing the first batch of shrimp, but it is too early to talk about any outstanding results.

Prospects of BFT in Ukraine

At the moment, this technology, if properly applied and promoted, can greatly change the production of aquaculture products.

This technology is ideal for growing tilapia, but it needs closed rooms to maintain the ideal temperature regime (28-29С).

https://www.youtube.com/watch?v=6qINURVigh8

In the summer, using this technology, you can grow almost all types of carp. At the end of September 2016, we plan to receive the first harvest of Nile tilapia grown on BFT in Ukraine.

One of the most promising uses of this technology can be the cultivation of crayfish in open water bodies. Thanks to the properties of this technology, crayfish can constantly have an additional source of food, which will significantly affect the possible cannibalism and growth of crayfish.

So join the pioneers of the aquaculture industry of Ukraine!