Since recently more and more questions have been appearing on the topic of which shrimp can be grown in our climate, I decided to give detailed answers to your questions in this article. If you still have more questions on this topic, please ask through the form below.

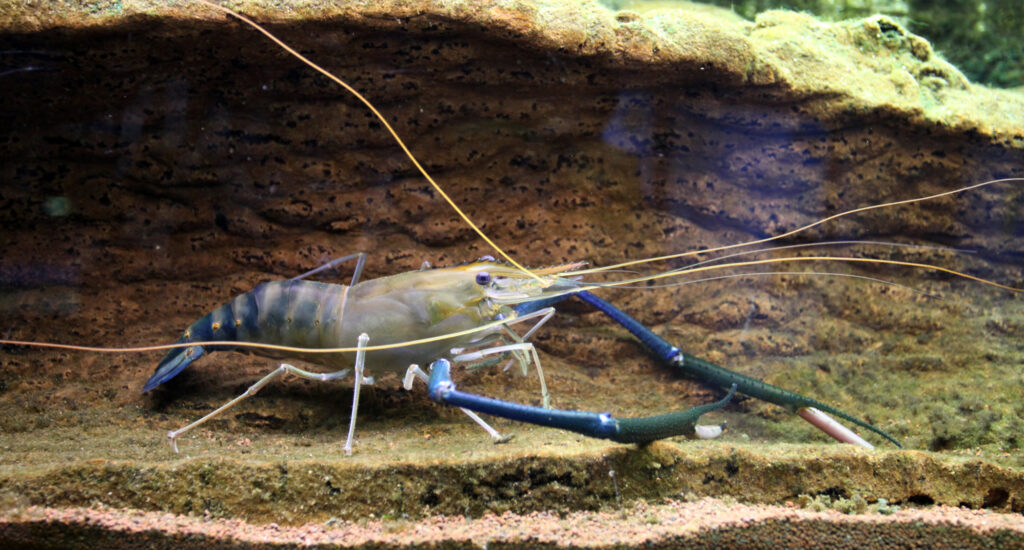

Well, I’ll go around and around, and let’s immediately take the bull by the horns. Currently, the most popular shrimp species for aquaculture are: Penaeus monodon (tiger), Penaeus vannamei (Pacific whitefoot) and Macrobrachium rosenbergii (Malaysian). The first two are marine, and the last is freshwater. In addition to these species, P. indicus (Indian), P. stylirostris (eastern blue) and a couple more species are also grown. But the most common and domesticated are the three above-mentioned species.

For cultivation Saltwater shrimp need water with a salinity of 15 to 35 ppt (15-35 kg of salt per 1000 liters of water). Growing temperature is from 17 to 34 (optimal – 28-30), oxygen requirement is not lower than 4 mg/liter. For freshwater shrimp, the conditions for temperature and oxygen are almost the same, but for their cultivation they need fresh water.

For cultivation, a postlarva at the age of 10-12 days (PL10-PL12) is purchased. This is the abbreviation for postlarvae. The numbers after the letters indicate the age of the individual in the postlarval stage. To the postlarval stage, a small shrimp goes from naupliia (zoea, mysis) to postlarvae in 10-15 days. Then the larva is raised for another 3-4 weeks, when it reaches a weight of 0.2-0.3 grams. And only after that it can be planted in permanent containers for growing.

Basic needs when growing shrimp:

- water temperature

- sea or fresh water

- availability of oxygen

- availability of quality feed

- product processing life activity

I suggest going through the above points to understand how it works. I am sure that after you read this article, there will be much fewer questions and you will understand that there is nothing extremely complicated in the process of growing shrimp.

And so, the temperature. I hope there is no need to explain how you can heat water. Everyone must choose the most optimal heating option for themselves. Heat sources can be solid fuel boilers, heat pumps, electricity, gas. Some farmers in the United States use cogenerators, which produce thermal and electrical energy when burning fuel. I read that somewhere in our Chernihiv region someone is trying to organize production, but so far they have not gotten around to getting to know this technology closely.

Remember that the better the building is insulated, the less you will need to spend on heating. But on the other hand: the warmer the building, the more expensive it is to construct.

To conserve heat, you need a building with the lowest heat loss coefficients. This can be an insulated hangar, an insulated building, and the simplest option is an industrial greenhouse. In the case of a greenhouse, you need to additionally insulate the walls of the pool. In my case, the walls of the pools will be additionally insulated using polystyrene foam, and a cover of bubble film will be placed on top. Remember that the better the building is insulated, the less you will need to spend on heating. But on the other hand: the warmer the building, the more expensive it is to construct.

I hope there are no problems with fresh water. But it is advisable to pre-filter this water through a mechanical multi-stage filter, as well as through an RAS device or an ozonizer. The task is to purify the water as much as possible from mechanical suspensions, as well as from possible pathogens. Before starting the post-larvae, the water must be thoroughly purged using aerators. Those. you need to turn on all the equipment in advance, 5-7 days before the launch of the larva. The water needs to be heated to the desired growing temperature. Remember that the postlarvae are sent in cool water to reduce oxygen consumption. Therefore, you need to very carefully adapt the shrimp larva to the water that you have. But I will write a separate article about this.

In the case of sea water, then for this you will need to dissolve sea salt in your prepared fresh water at the rate of 15-25 kg of salt per 1000 liters of water. Not just any sea salt is suitable; you need a special artificial salt with an ionic composition close to ocean water.

By the way, there is no need to change the water in pools. You can only add as it evaporates.

Good and reliable controllers are quite expensive, but they really allow you to save the harvest.

Since we will have very warm water and a dense pack of shrimp (6-8 kg per 1 m3), oxygen saturation is carried out using special nozzles. It is necessary to constantly monitor the oxygen level using special controllers. Modern controllers even allow you to remotely receive data on the state of the reservoir. Also, using these controllers, you can connect an emergency supply of pure oxygen (or additional aerators) in case of unforeseen situations. Good and reliable controllers are quite expensive, but they really allow you to save the harvest.

Shrimp are very selective in their feed.

A very important topic is feed. Shrimp are very selective in their feed. If you have ever been able to watch a shrimp eat in an aquarium, you could see that it very carefully selects those pieces that suit it best. This is not a fish that swallows food whole. The shrimp waits for the food to swell a little and then selects the most delicious pieces from there. The task of food manufacturers is to create food of such density and with such components that the shrimp absorbs as many tasty parts as possible. To grow one kilogram of feed you need 1.5-2 kilograms of feed. The cost of imported feed is about 2.5-3 Euro per kg. Shrimp feed uses up to 25% high-quality fishmeal.

The processing of waste products is carried out using modern technology, which is called bioflocculation. Many books have been written on this topic, but to explain in simple human language, the breakdown products of proteins (ammonium) are processed using bacterial flakes. In addition to bacteria, these flakes contain protozoa, rotifers and other small fry. The shrimp themselves also feed on these flakes. In order for this technology to work, aerobic conditions (with access to oxygen) must be created; these flakes must be constantly suspended so that all residents of these microcolonies receive the required amount of oxygen. To do this, the water in the pools is actively mixed using aeration, pumps, airlifts, etc. The optimal amount of these flakes in water is 15 ml for every 1000 ml of water. To remove excess flakes, precipitation columns (hydrocyclones) and protein flotators are used, from where the sediment is discharged into the sewer system. I will talk about bioflocculation technology in more detail a little later.

For every 100 m3 of water you will need about 2 kW/hour of electricity.

That’s it, very briefly about the technology of growing shrimp in our conditions. The scheme that I propose is called super-intensive. It allows you to obtain up to 20 kg of grown products from 1 m3 per year. For every 100 m3 of water, you will need about 2 kW/hour of electricity.

By the way, using the same bioflocculation technology, you can grow carp and tilapia, which happily consume bioflakes for food. I think that this technology will also be promising for growing crayfish. When summer comes, we’ll try.

If you are interested in building a farm for growing shrimp, I advise you to familiarize yourself with the figures of the project “Shrimp-5”.

You can find my contacts on the page Contacts. Earn money!

Good luck!